Lcl and ucl calculator

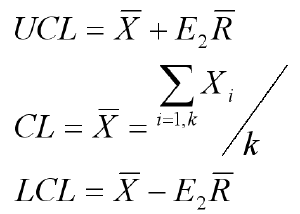

LCL X-bar X-bar-bar A2 x R-bar Plot the Lower Control Limit on the X-bar chart. I will put the example here.

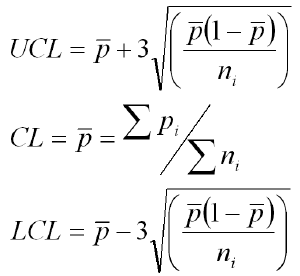

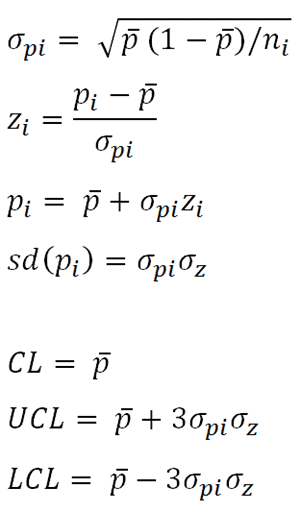

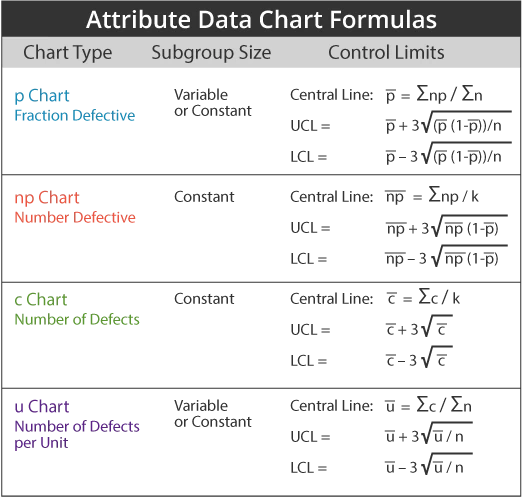

U Chart Calculations U Chart Formula Quality America

In this example type F73F8 without quote marks in cell F9.

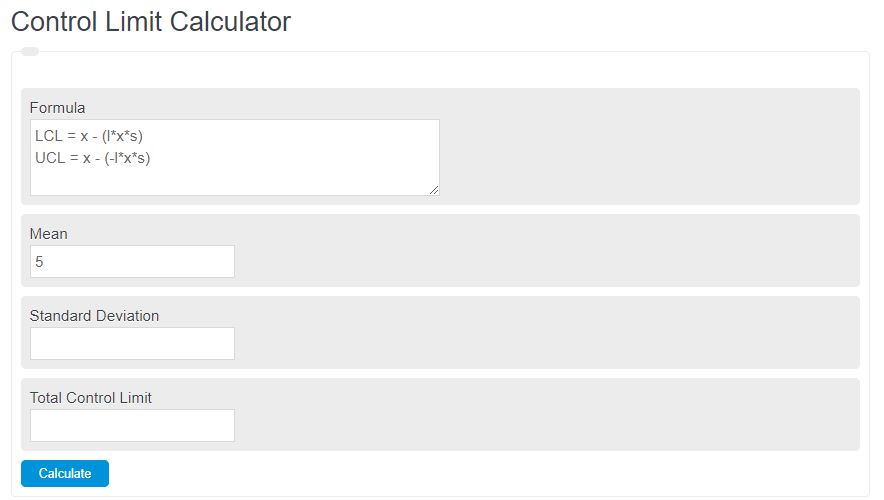

. This is the average. Control Limit Calculator This is an online calculator which can be used as part of the QC. Calculate the Upper Control Limit UCL which is the mean of means plus three times the standard deviation.

Mean and Standard Deviation Xbar-S chart is used when you have. What is LCL and UCL in statistics. UCL Upper Control Limit.

LCL Lower Control Limit. The control limit formula is x bar E2. Code to add this calci to your website Just copy and paste the below code to your webpage where you want to.

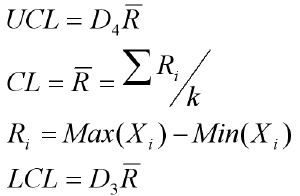

UCL - LCL calculated with average. Calculate and enter the average defective proportion total number of defectives total number of samples in this cell. X Control Chart CL X double bar 1294 UCL 1294 577 135 13719 Note that we are using 5 subgroups so on the chart n 5 and.

Add the UCL formula. Still I have not been able to achieve by main goal since percentile and control chart are two separate things. Then calculate the average of these 29 values.

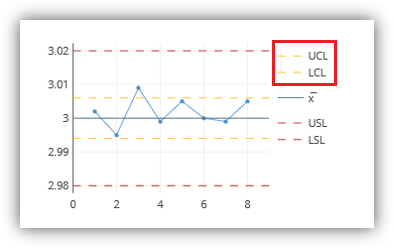

The UCL Upper Control Limit and LCL Lower Control Limit for a numerical column calculated in excel is differ from the UCL and LCL calculated by minitab for the same. Here is an example. Calculation of Upper UCL and Lower LCL limits for SPC charts There are 2 types of SPC charts X charts the measure central tendency And R charts that measure dispersion.

You can type this formula. Use this chart to determine the Upper Control Limit UCL and Lower Control Limit LCL for an Xbar-S chart. The lower control limit lcl calculator finds the lower and upper limits of control.

First lets check how to determine the lower LCL and upper UCL limit. Simple steps to add UCL and LCL in excel chartPlease support by subscribing to my channel. For our Exercise the details are as follows.

UCL X-bar X-bar-bar A2 x R-bar Plot the Upper Control Limit on the X-bar chart. Consider these steps to chart an upper. The Levey-Jennings Control Chart lesson in the Basic QC Practices series.

If you entered 10 20 30 100 and use 2 samples to calculate the moving range then you have an average moving range mR bar of 10. U chart for defects flaws per unit Occurrence per unitStatistics in Excel Playlist. MR2 the absolute absolute value of the third value - second value and so on.

Enter a value between zero and one Sample Size in the last sample. You will have 29 of these values. How do you calculate UCL and LCL in a control chart in Excel.

Once youve calculated your average of averages standard deviation and averages type the formula for the upper control limit. If the mean was 21 and the standard deviation was 7 should my UCL then be 42.

Control Chart Limits Ucl Lcl How To Calculate Control Limits

Control Chart Wizard Average And Standard Deviation

X Bar R Chart Formula Xbarr Calculations Average And Range

C Control Charts Bpi Consulting

36484 How Are Control Limits Calculated For The Different Shewhart Control Charts

Control Limit Calculator Calculator Academy

What Are Ucl And Lcl Limits In Trendable Trendable

Calculating Control Limits For A C Chart By Hand Youtube

P Prime Control Chart Formulas Laney P Chart Formula P

Statistical Process Control Spc Tutorial

U Control Chart Formulas U Chart Calculation

X Bar R Chart Formula X Bar R Chart Calculation Calculate X Bar R Chart

Spc Calculating Upper Lower Control Limits Youtube

Control Chart Limits Ucl Lcl How To Calculate Control Limits

Control Chart Wizard Average And Range X Bar And R

P Chart Calculations P Chart Formula Quality America

2